September 16, 2025

How Humidity Affects Air Quality Monitor Accuracy

Why Humidity Disrupts Air Quality Sensor Performance

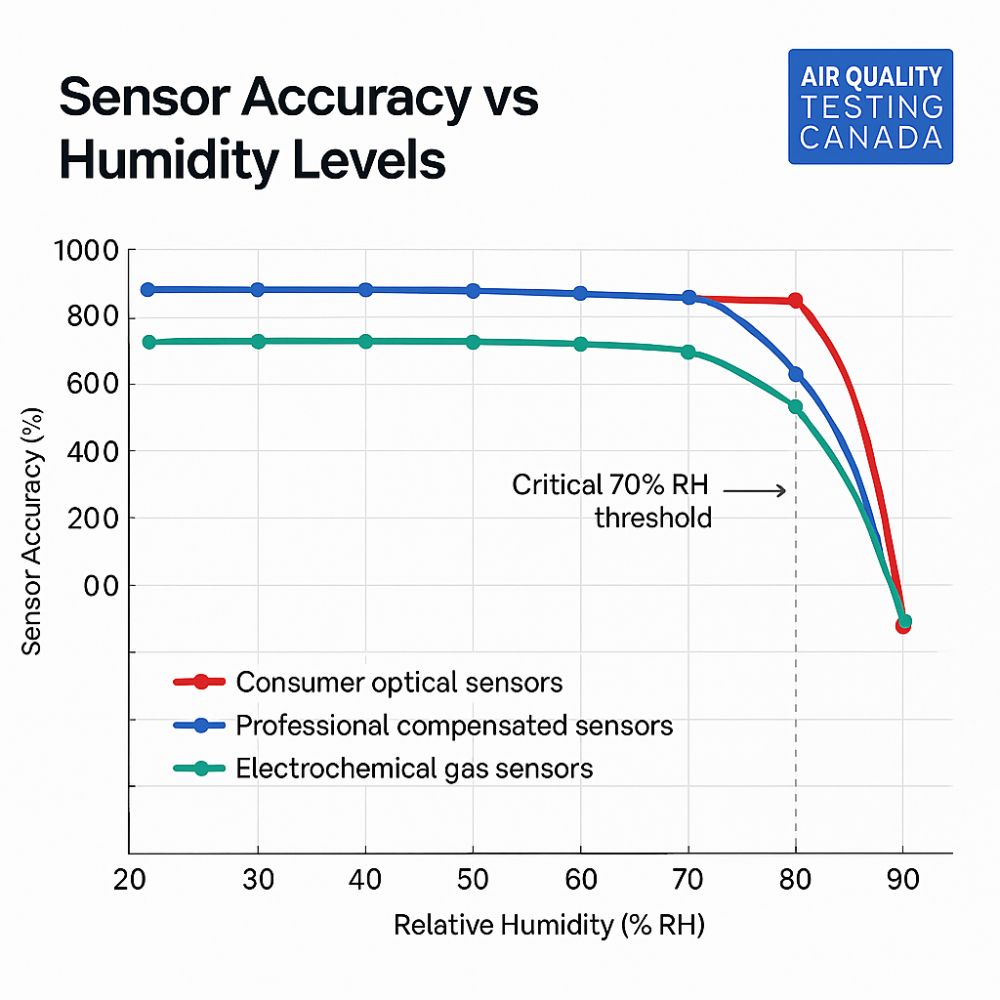

Air quality sensors struggle with moisture because water vapor interferes with their detection mechanisms. Most consumer and professional monitors use optical, electrochemical, or semiconductor sensing technologies that respond differently to humidity levels.

Electrochemical sensors measuring gases like carbon monoxide show 5% accuracy variations when relative humidity increases from 15% to 48%. Volatile organic compound (VOC) sensors experience even greater disruptions, with some models showing 15-30% reading deviations in humid environments.

The science behind these errors involves several physical processes. Water molecules compete with target pollutants for sensor surface area. Temperature changes from humidity create thermal drift in electronic components. Condensation can temporarily disable optical sensors until moisture evaporates.

Indoor vs. Outdoor Humidity Impact on Air Quality Readings

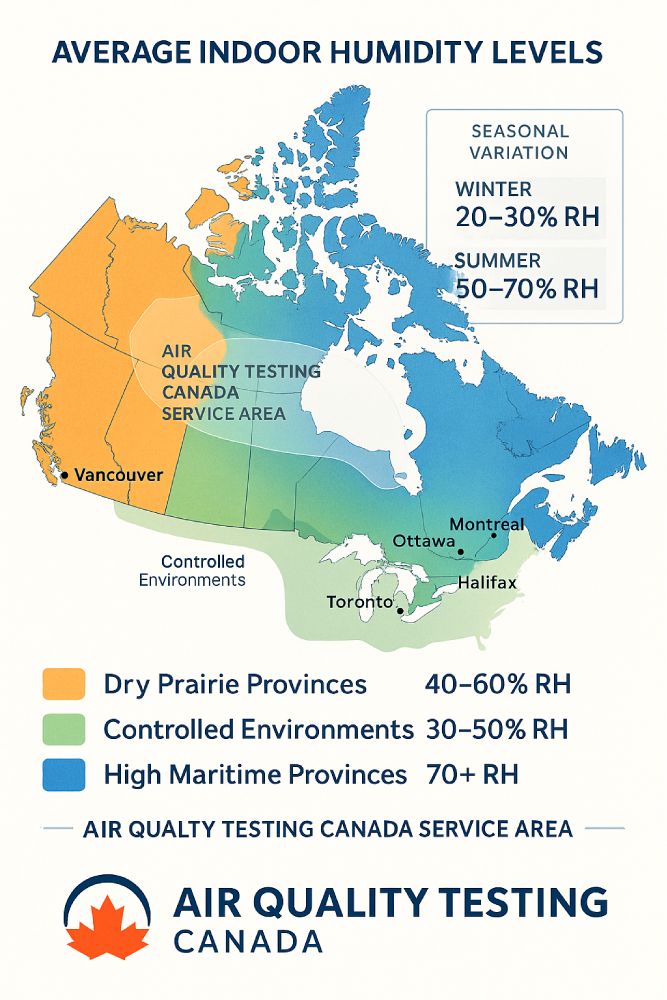

Basements and crawl spaces common in Ontario and Quebec homes often maintain 60-80% relative humidity year-round. Air quality monitors in these spaces consistently over-report particle concentrations because particles absorb moisture and appear larger to optical sensors.

Commercial buildings with HVAC systems typically maintain 30-50% relative humidity, following Health Canada guidelines for optimal indoor air quality. Sensors in these controlled environments provide more accurate readings because moisture levels stay within calibrated ranges.

How Relative Humidity Changes Actual Pollutant Behavior

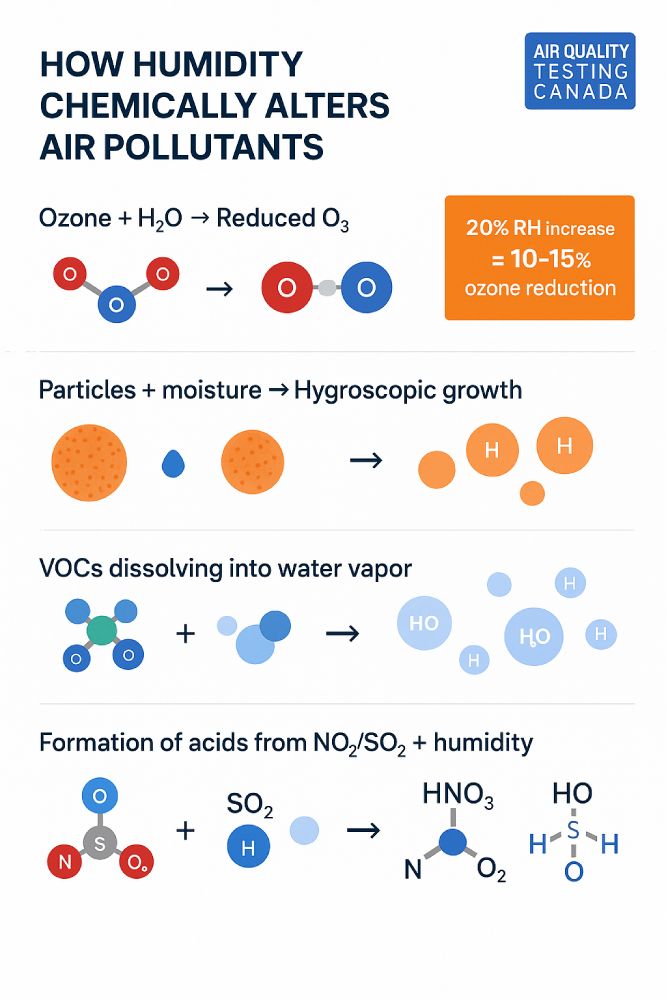

Ozone concentrations decrease in high-humidity conditions through chemical reactions with water vapor. A 20% increase in relative humidity can reduce actual ozone levels by 10-15%, independent of sensor measurement issues. This means sensors showing stable ozone readings during humid weather may actually indicate improving air quality.

Volatile organic compounds (VOCs) behave differently in humid air. Some VOCs dissolve into water vapor, reducing airborne concentrations. Others undergo chemical reactions that create new compounds with different health impacts. Professional residential air quality testing accounts for these chemical changes, while consumer monitors typically only measure sensor response.

Which Air Quality Sensors Are Most Affected by Humidity

Optical particle counters, used in most consumer PM2.5 monitors, show the highest humidity sensitivity. These devices measure light scattering from particles, and water-swollen particles scatter more light, creating inflated readings. Professional-grade optical sensors include humidity compensation algorithms, but most consumer devices lack this correction.

Humidity Effects Across Different Canadian Climate Zones

Maritime provinces experience consistent high humidity, with annual averages above 70% relative humidity. Air quality monitors in Halifax or St. John’s consistently over-report particle concentrations, requiring professional calibration with local humidity compensation factors.

Ontario and Quebec face extreme seasonal humidity variations. Toronto summers reach 80% humidity while winters drop below 20%. This 60-point swing challenges sensor accuracy throughout the year. Professional testing companies like Air Quality Testing in Ottawa adjust calibration protocols quarterly to maintain measurement reliability.

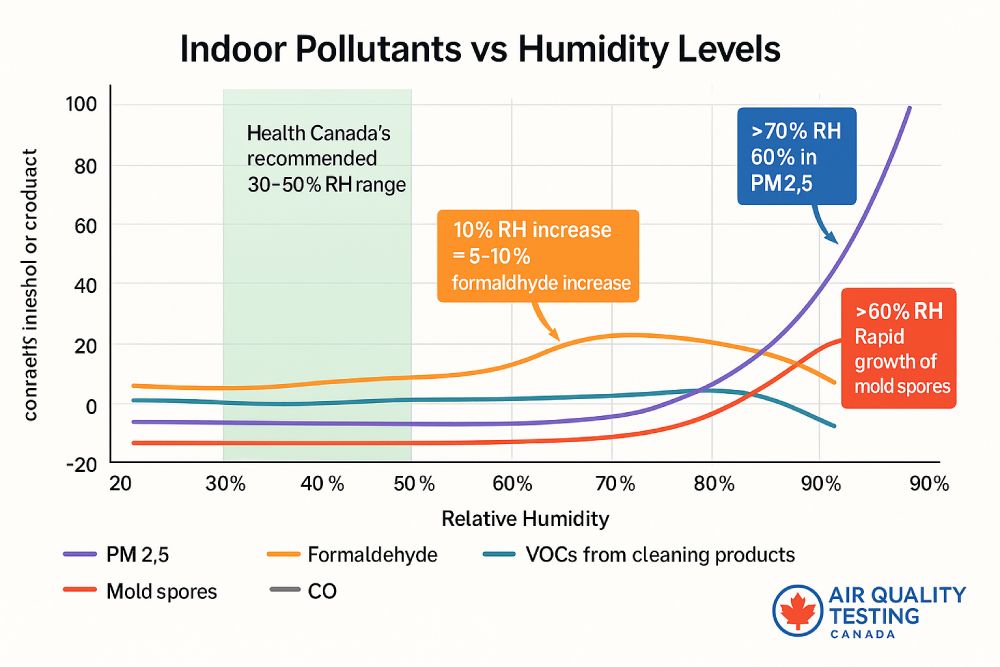

Humidity’s Impact on Common Indoor Air Pollutants

PM2.5 particles show the most dramatic humidity response, increasing measured concentrations by 40-80% when relative humidity exceeds 75%. This effect varies by particle composition – salt particles grow more than organic particles, creating different error patterns in coastal versus inland locations.

Volatile organic compounds (VOCs) demonstrate complex humidity relationships. Formaldehyde levels actually increase in high humidity as moisture accelerates off-gassing from building materials. Conversely, many cleaning product VOCs decrease as they dissolve into water vapor, reducing airborne concentrations.

Professional Calibration Solutions for Canadian Conditions

Multi-point calibration involves testing sensors at 17%, 30%, and 48% relative humidity using NIST-traceable humidity chambers. This process identifies each sensor’s humidity response curve, enabling mathematical correction of field measurements. Air Quality Testing Canada performs these calibrations using equipment traceable to National Research Council standards.

Automated humidity compensation uses real-time relative humidity measurements to adjust air quality readings mathematically. Professional monitoring systems include calibrated humidity sensors and algorithms that correct PM2.5, VOC, and gas measurements based on current moisture conditions.

When to Choose Professional Testing Over Consumer Monitors

Consumer monitors work adequately in controlled indoor environments maintaining 30-50% relative humidity. Office buildings, shopping centers, and well-maintained homes with HVAC systems fall within this category. However, readings should be interpreted as trends rather than absolute values.

Professional testing becomes essential when humidity exceeds 65% or drops below 25% consistently. Basements, bathrooms, swimming pool areas, and buildings with poor climate control require professional assessment to separate actual air quality problems from humidity-related measurement errors.

Frequently Asked Questions About Humidity and Air Quality Testing

Seasonal Calibration Protocols for Canadian Buildings

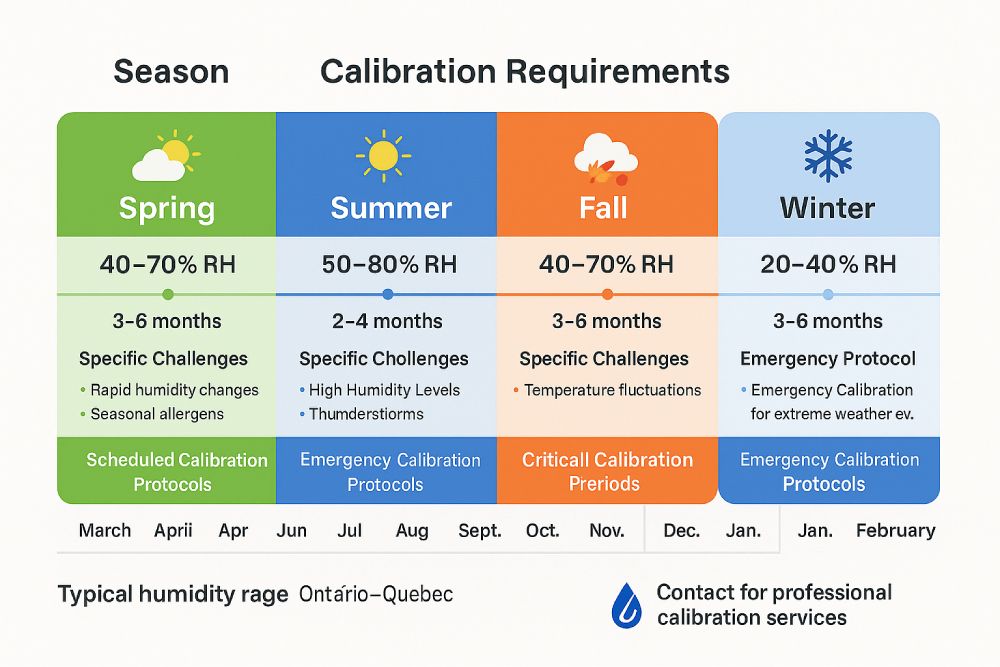

Spring calibration addresses humidity increases as snow melts and outdoor moisture rises. Sensors require adjustment for 40-60% humidity ranges common during April-May transition periods. Professional testing companies perform comprehensive recalibration during this season to prepare for summer challenges.

Summer protocols focus on high-humidity compensation, especially for basement and ground-level monitoring. July-August humidity often exceeds 80% in many Canadian locations, requiring aggressive correction factors for particulate matter sensors. Professional monitoring systems switch to summer algorithms automatically.

Maintenance Best Practices for Humid Environments

Monthly sensor cleaning prevents moisture-related contamination buildup that affects accuracy. Professional protocols include isopropyl alcohol cleaning for optical surfaces and compressed air cleaning for inlet ports. Consumer devices often lack access to critical components requiring professional service.

Inlet protection prevents water intrusion during rain or condensation events. Professional installations include heated inlet lines and protective housing designed for Canadian weather conditions. Consumer monitors typically lack these protections, limiting outdoor application reliability.

Get Professional Air Quality Testing That Accounts for Canadian Climate

Don’t let humidity compromise your air quality assessment. Our certified experts provide humidity-compensated testing across Ontario and Quebec, ensuring accurate results regardless of seasonal conditions.

📞 Call 1-866-528-2897 📋 Request Quote 🔬 Our ServicesRelated Air Quality Testing Services

Residential Testing

Commercial Testing

Asbestos Testing

Serving Canadian Communities

Professional air quality testing services across Ontario and Quebec: